The manufacturer of ultrasonic welding equipment for mask production, among other things, wanted more process reliability when machining difficult-to-cut materials: With tools from Paul Horn GmbH and cooling lubricants from Zeller+Gmelin, the Karlsbad-based specialist for ultrasonic components and systems was able to find two suitable partners.

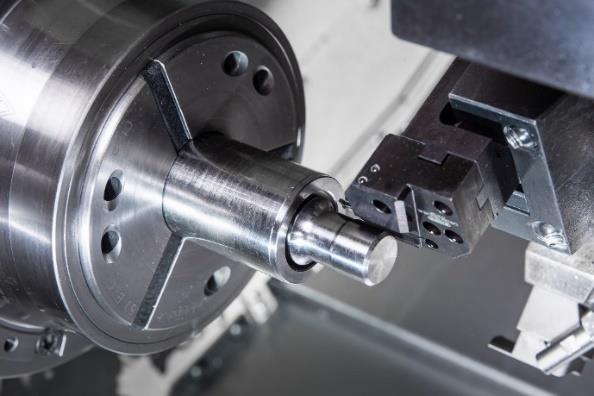

The ultrasonic systems are used, for example, in the manufacture of a wide variety of medical technology applications, such as medical masks or medical components such as membranes, adapters and connectors, through to surgical instruments. In particular, demand for ultrasonic welding technology for the series production of medical masks made from nonwovens has skyrocketed due to the pandemic. Weber Ultrasonics' vertical range of manufacture is enormous: almost all components and assemblies of the ultrasonic systems are manufactured in-house. For a special titanium component, the so-called converter, grooving is used as a machining process, more precisely axial grooving. New tool solutions were sought in order to guarantee process reliability and a long service life even with increasing quantities. Chatter marks on the surface of the deep grooves had previously been a recurring problem.

Zubora ensures greater process reliability

With a new axial grooving system from the Tübingen-based tool specialist Horn, a process-reliable

solution was found: the new S15A grooving insert immediately resulted in a stable machining process. At the same time, Zubora TTS, a new cooling lubricant developed in a joint project between Horn, Zeller+Gmelin and a major machine manufacturer, is being used. "All the experience of the lubricant manufacturer, machine builder and tool specialist has been incorporated into the development of the new lubricant," says Jürgen Schmid, Product and Project Manager Sales at Horn, seeing an enormous advantage. "The idea of the project was to develop a new and more efficient cooling lubricant for machining superalloys.

Zeller+Gmelin has achieved this with the development of the new KSS." And Business Unit Manager Thorsten Wechmann from Zeller+Gmelin adds: "After successful tests in various superalloys, the first field test at Weber Ultrasonics was now on the agenda. By using Zubora TTS in combination with a new tool coating, it was possible to significantly increase tool life. The completely new formulation not only increases tool life but also improves the surface quality of the component. In addition, it was possible to increase the cutting parameters and thus sustainably increase profitability."

Chip breaking under control

According to Weber Ultrasonics, it has been possible to significantly improve chip control by optimally coordinating the tool and cooling lubricant. The problem of uncontrolled long chips is now a thing of the past. Tool wear has also improved measurably and visibly thanks to the new Zubora coolant.

The new cooling lubricant Zubora TTS is a fully synthetic solution. According to the manufacturer Zeller+Gmelin, the focus of the new concept was on lubrication, supporting chip breaking and improving surface quality. "We developed the new coolant lubricant for the productive machining of titanium and other superalloys. However, the product is multifunctional and also offers advantages when machining a variety of other materials," explains Thorsten Wechmann.