The spray cleaner achieves the required result even at room temperature and thus significantly reduces the energy consumption in so-called power wash systems. The focus is on energy efficiency and environmental compatibility while maintaining outstanding product performance. Zeller+Gmelin will be showcasing the spray cleaner at PaintExpo 2022 in Hall 1, Stand 1320. The world's leading trade fair for industrial painting technology will take place in Karlsruhe from April 26-29, 2022.

Customers at Zeller+Gmelin do not have to compromise when it comes to the environmental friendliness and versatility of the Divinol spray cleaner product range. Jonas Wasserka, Head of PCH at Zeller+Gmelin, emphasizes: "With our aqueous cleaners for powerwash systems, we are able to achieve

paintable surfaces on all common plastics. We offer alkaline and acidic products for a wide range of applications - and some of them are completely label-free!"

Divinol Spray Cleaner 1362 KC has a high biostability and therefore does not require biocides. It can be used without disturbing foam formation. Due to the low process temperature, less water evaporates during operation of the Powerwash system, which also reduces fresh water consumption.

For Jonas Wasserka, saving energy is the convincing argument: "Using less energy helps to save resources and automatically protects the climate."

The topic of sustainability and climate protection is very important to the long-established company from Eislingen. In January 2020, Zeller+Gmelin qualified as a "climate-neutral location".

All products - including the new Divinol Spray Cleaner 1362 KC - are produced, stored and delivered in a climate-neutral way.

Top results at low temperatures

More economical, more environmentally friendly and process-stable - this is the credo of Zeller+Gmelin. With the Divinol spray cleaner 1362 KC, considerable energy savings can be made. In use, temperatures from 25 °C in the Powerwash system are sufficient to achieve optimum results. There is no need to heat up and maintain high process temperatures throughout. Pre-treatment and therefore the entire painting process become more economical.

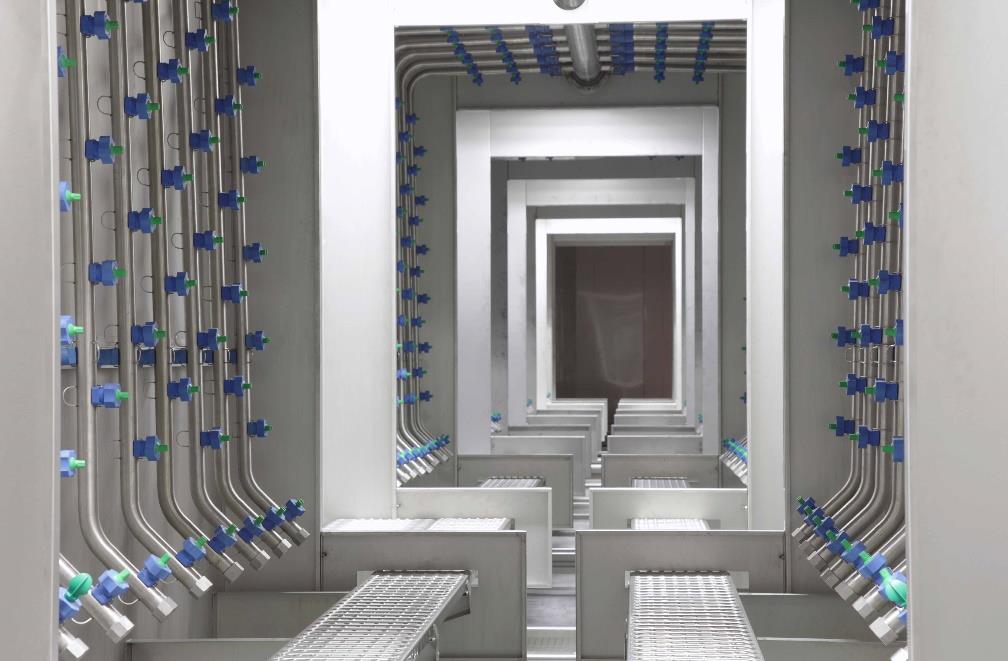

Caption: The Divinol spray cleaner 1362 KC significantly reduces the energy required for power wash systems. It is no longer necessary to heat the bath temperature to 60 °C. It achieves the required cleaning performance in the powerwash system even at room temperature. (Image source: b+m surface systems GmbH)